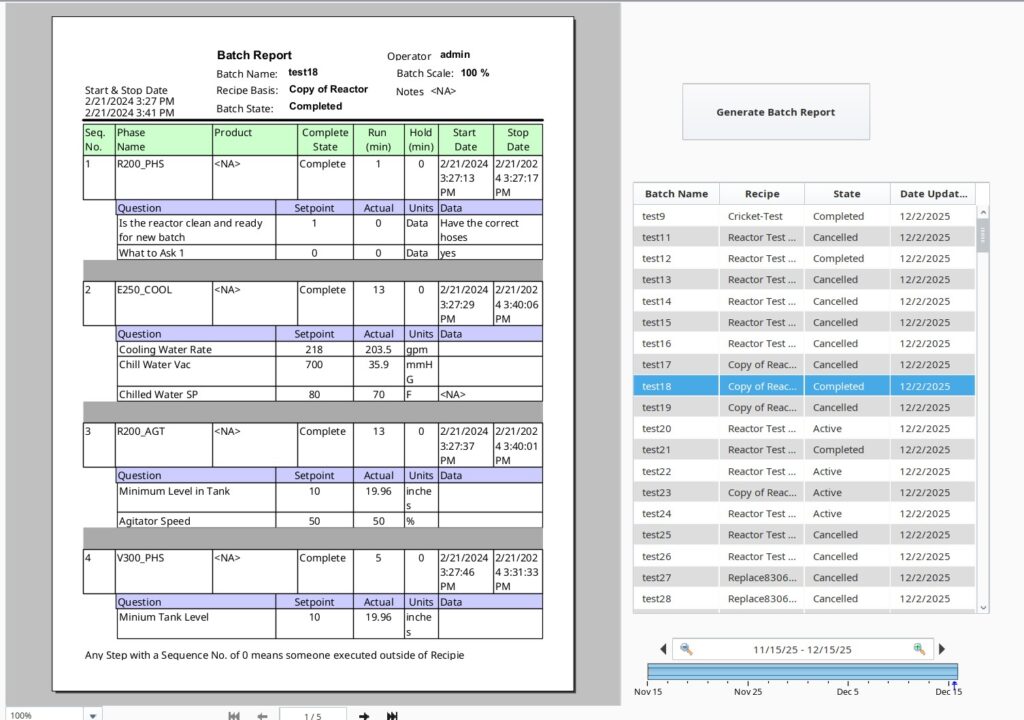

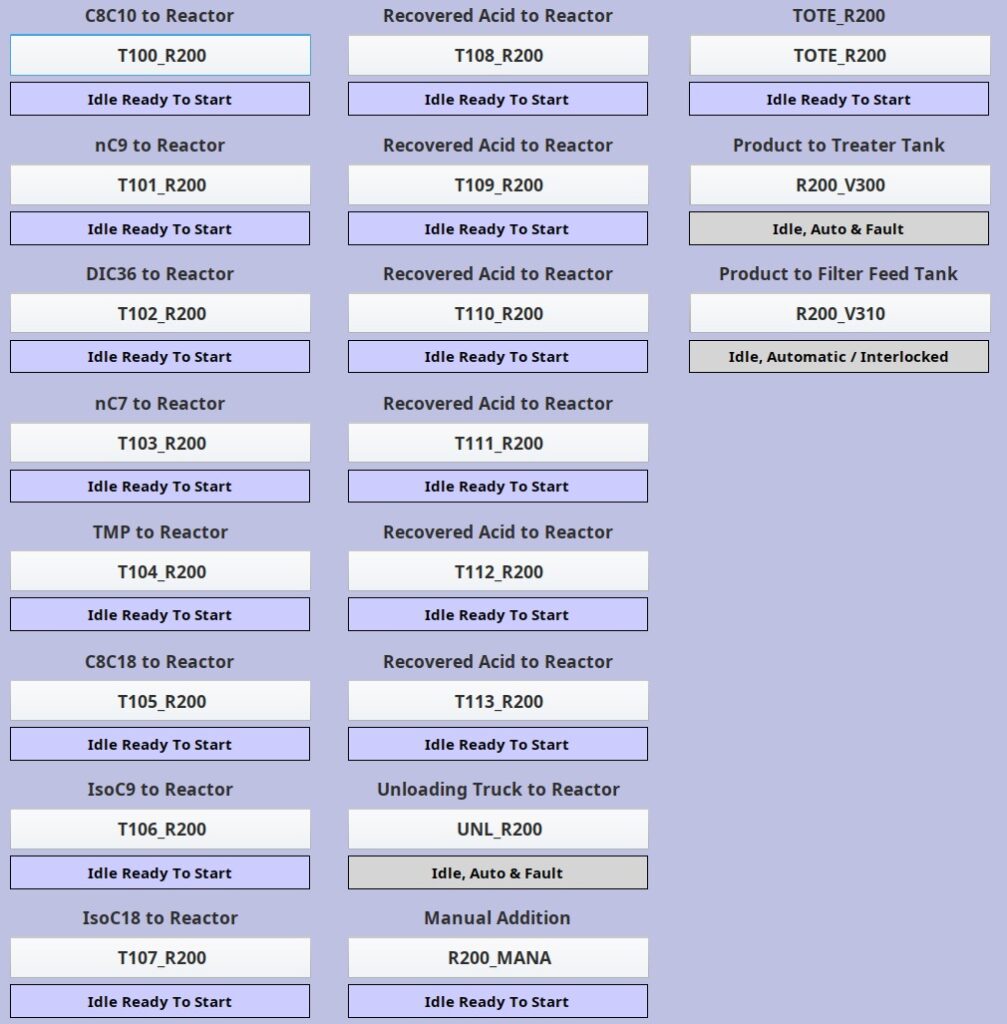

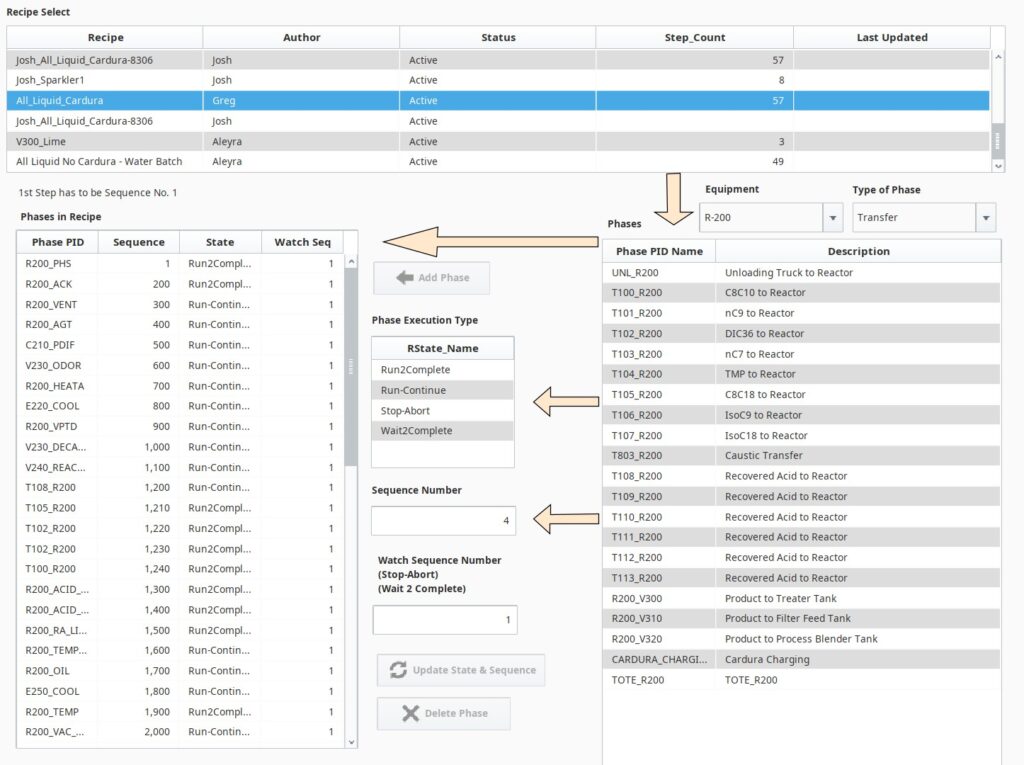

Ramboll has built our S88 platform on Inductive Automation Ignition. It allows for us to control the batch and phase control code inside the Ignition platform. SQL database is used for the core configuration and data collection. Since we have control of the code we can adjust it to customer needs.

Ramboll will work with you to define the process with our methodology.

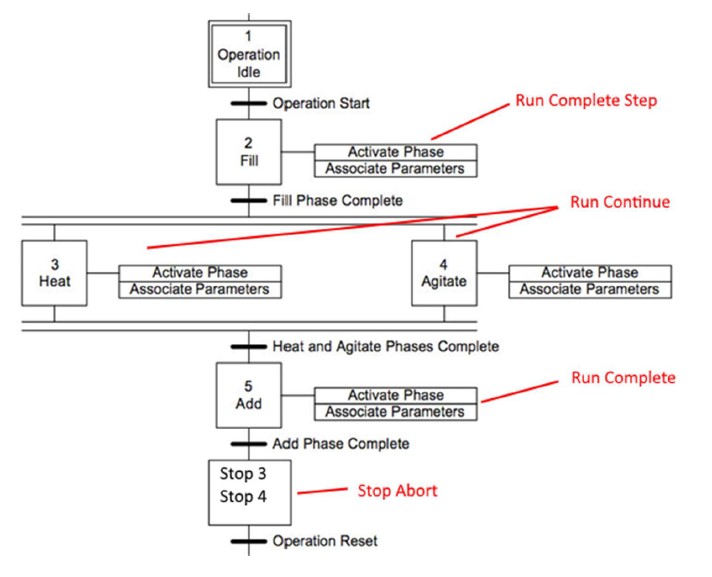

We will go through each phase and detail the steps for each one. Then we will develop a matrix to show the interlocks between the phases.

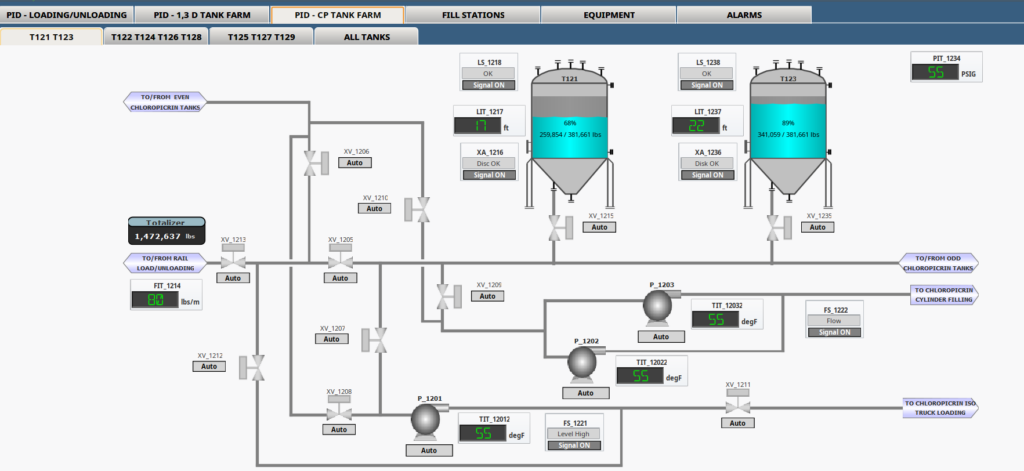

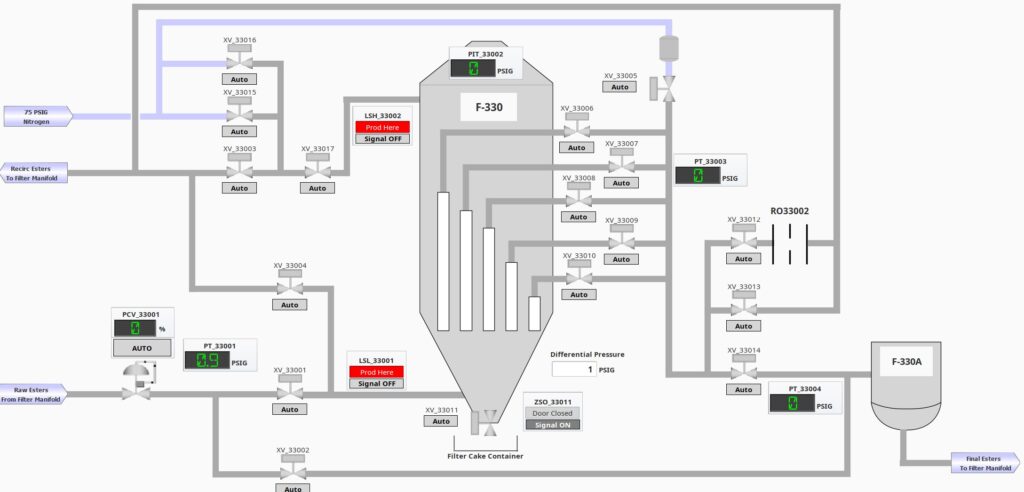

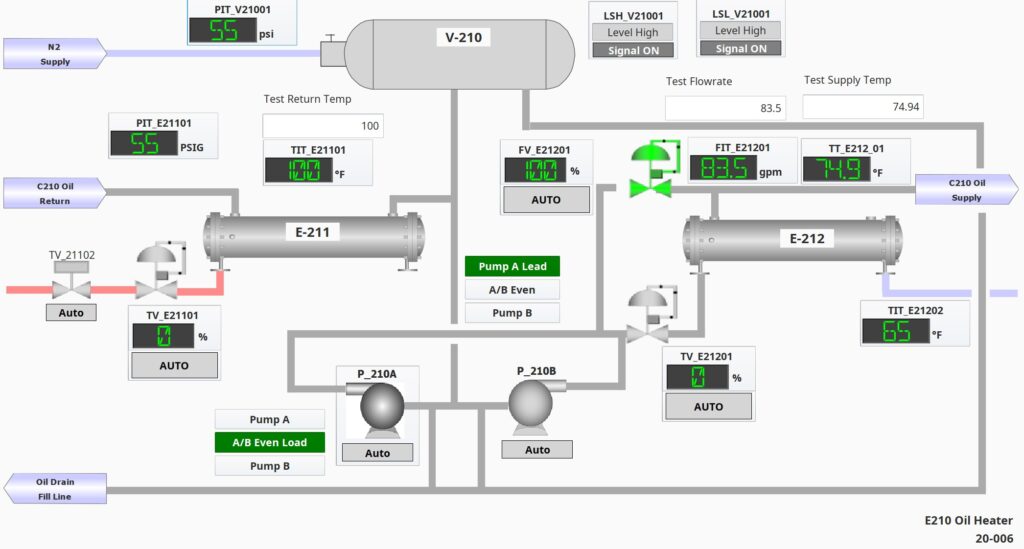

For instruments and equipment we have pre-made Add-On-Instructions, User Defined Templates, and Pop-ups for consistency across the P&ID screens.

Guiding your business through the project

Our team is dedicated to providing you with the best solution customized for your business

FAQs

Why base it in Ignition?

Modern plants have different pieces of equipment with different controllers. Ignition allows us to combine your HVAC, Process Automation Controller, and other vendor equipment into one unified platform. You are not locked into a specific vendor platform or equipment.

How long has this been implemented in the field?

We have implemented this solution in a variety of specialty chemical plants and regulated facilities. The oldest facility has had this system operational since 2017, and this customer has expanded the system into another facility.

How open is the database information?

We have built our system to have the data readily available, and we share the schema and layout with our clients. We are truly open with the structure and code with our clients.

Will you allow other controls people to work on the system?

Certainly!!! We our happy to train your in-house controls people or external contractors on the use and configuration of the system so you can be self-sufficient. Or if you don’t have those resources we can continue to help with whatever you need going forward, doing as little or as much as you need. Either way we will make sure you are supported!