Ramboll can help you with your chemical process. We can digitally twin your facility with our controls system to allow you to see how it all works well before you have an operational site.

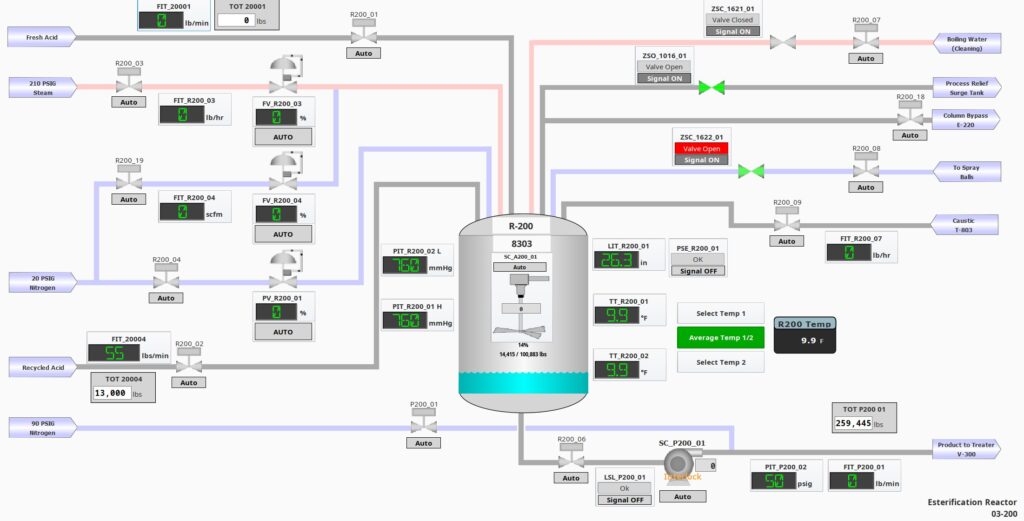

P&ID Screens

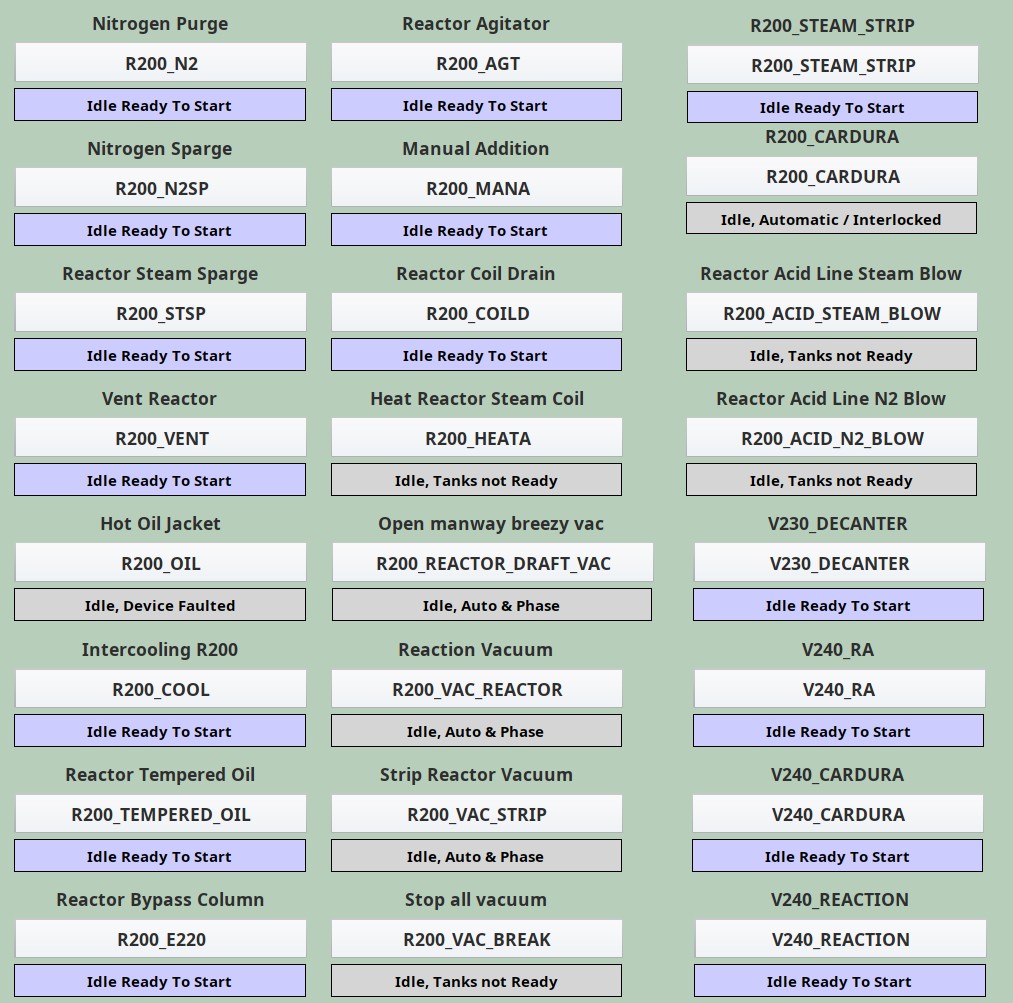

Phases Build to Run

Process and Automation engineers working together to develop the correct solution for you.

Many teams just have one process group and another group for automation. This typically adds a disconnect on how everything is supposed to operate.

Here at Ramboll we have both the process and automation engineers working together for the best solution.

One pane of glass to see the operations from anywhere in the plant. HMIs anywhere you want them.

SIL2 and SIL3 capable Safety Instrumented Systems (SIS) along with Process Hazard Analysis (PHA) studies to determine the best method to protect your investment.

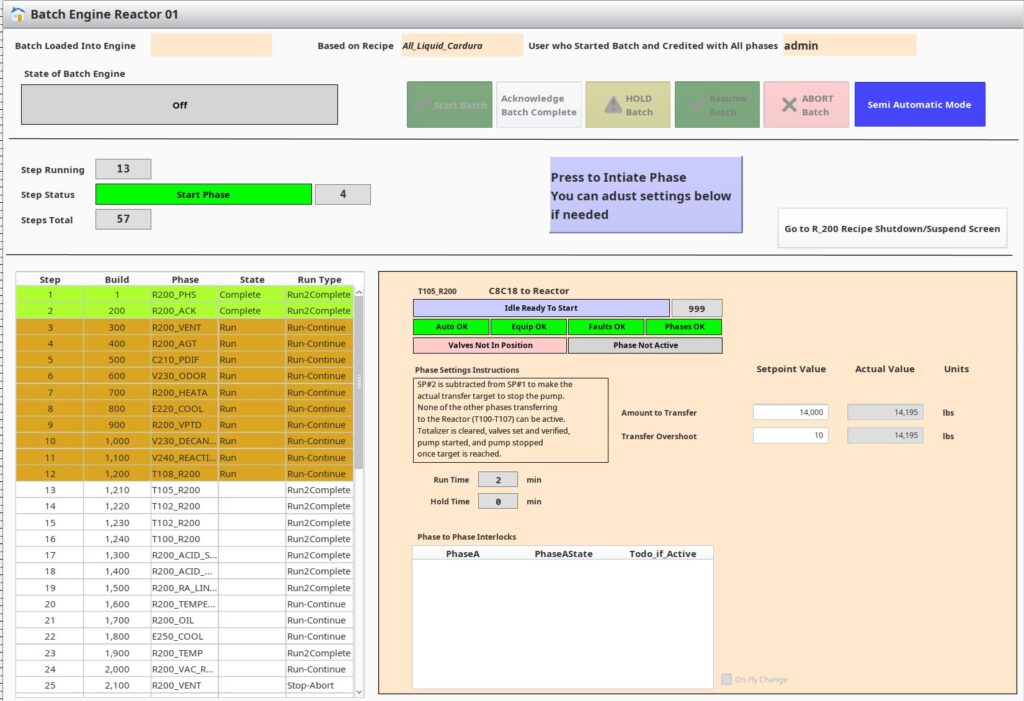

Recipe and batch solutions

Your recipes and batch sequences are highly guarded intellectual property. We build our system to allow you to create your own recipes without the need for an automation engineer. We train your team to build and adjust your own recipes without any automation engineers.

FAQs

What is S88?

S88 is an ANSI/ISA-9901 standard for process control. It uses key terminology and guidelines to define each process as a phase that can be programmed as a repeatable unit. It effectively allows us to setup the “kitchen” to let you make anything you want.

What is a phase?

A phase is a sequence that is typically a transfer of product, process action, or a procedure than can be quantified and programmed with or without human interaction to execute within a system. Each phase can be interlocked to other phases to prevent undesirable affects.

What is recorded?

Every phase that is executed – whether in a recipe or independent – is recorded in the SQL database. Any analog signals, digital, and other items can be recorded based on customer preference with the built in Inductive Automation Historian. All this information is structured in SQL for ease of data analysis by the SCADA or 3rd party tools.

What is the Hardware and Software platform?

The system is based on a PLC/PAC control platform with Inductive Automation Ignition platform as the SCADA. With the rise of Process Automation Controllers (PAC) and Inductive Automation SCADA the need for a DCS is no longer needed and can be retired. These modern systems are lower cost and easier to service, upgrade, and expand as the plant evolves over the years.

Why Use Ramboll S88 platform?

Ramboll design the core code for the S88 sequencing and interaction. This allows us to modify the code if the customer has specific requirements or situations that are unique. We are not locked into a canned solution that is a black box. Our code IP license is free to our clients who utilize our services; we are your partner in this, not just a vendor.

Connecting to an ERP system is second nature and we have proven methods to keep your ERP system up to date with the information needed.

Why we use Ignition for our Solution?

- PLC / PAC agnostic

- Connect different vendors and systems as one unified front

- You want another Terminal or portable tablet? No problem – and unlike other systems there is no additional licensing fee for additional HMIs!

- Best in class SCADA